Headquartered in China, Wonder has more than 10 years of custom CNC manufacturing experience. We are able to offer custom CNC machining services and laser cutting services from design, rapid prototyping, and complex parts geometry to low or large-volume production. We are always committed to producing high-quality machined parts and laser cutting parts in line with your budget and lead time demand.

Precision Machining

- Home

- Precision Machining

"One Dream, for Making better Precision Parts".

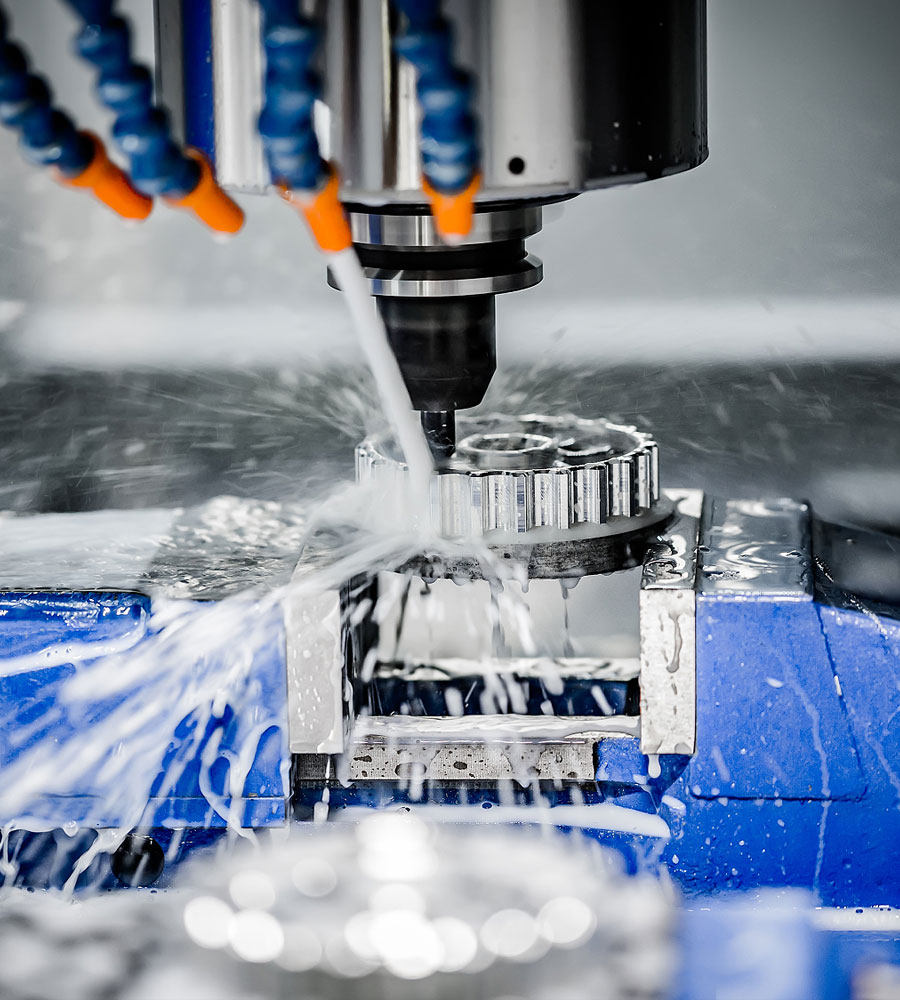

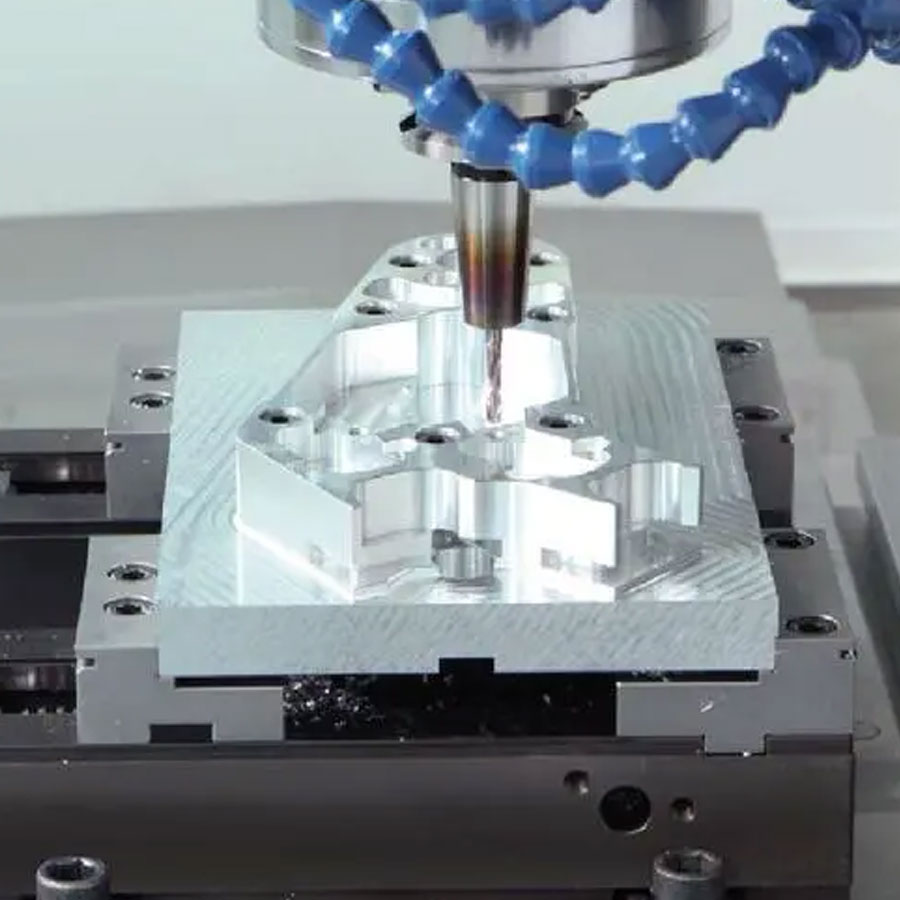

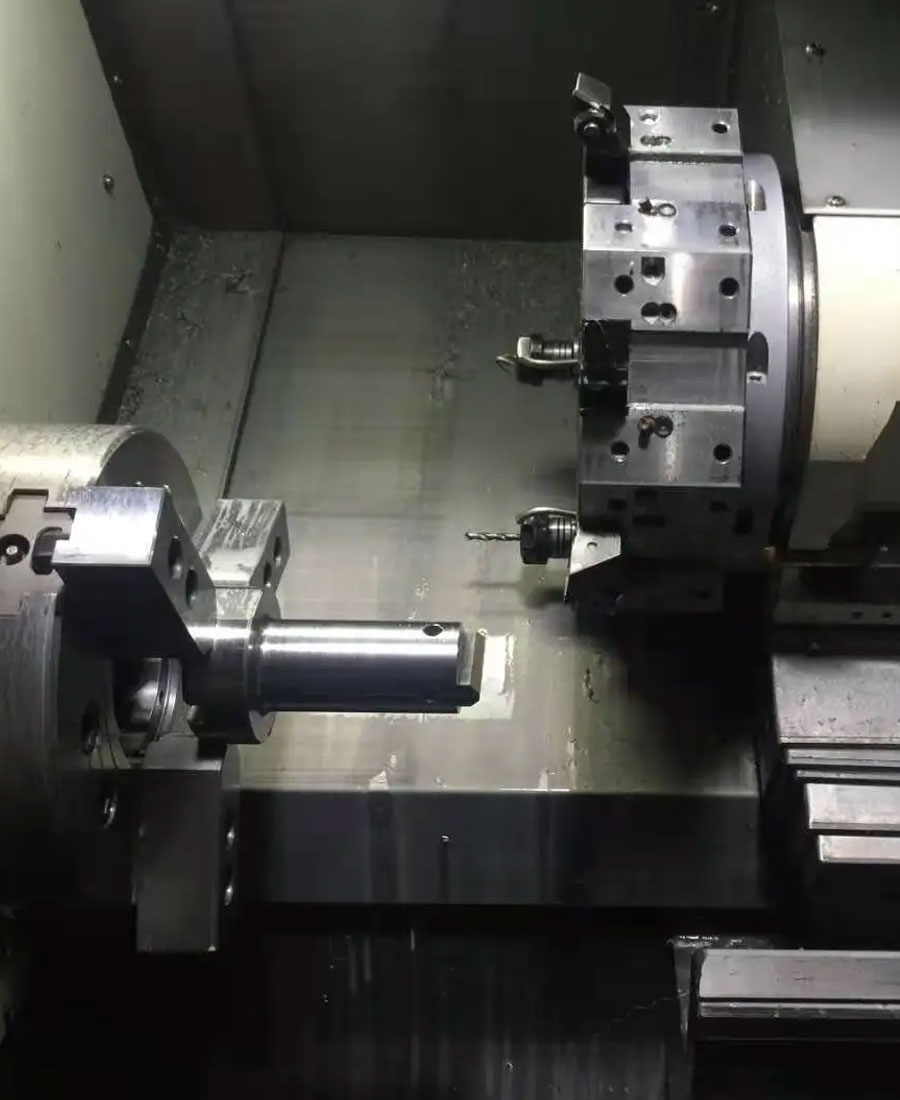

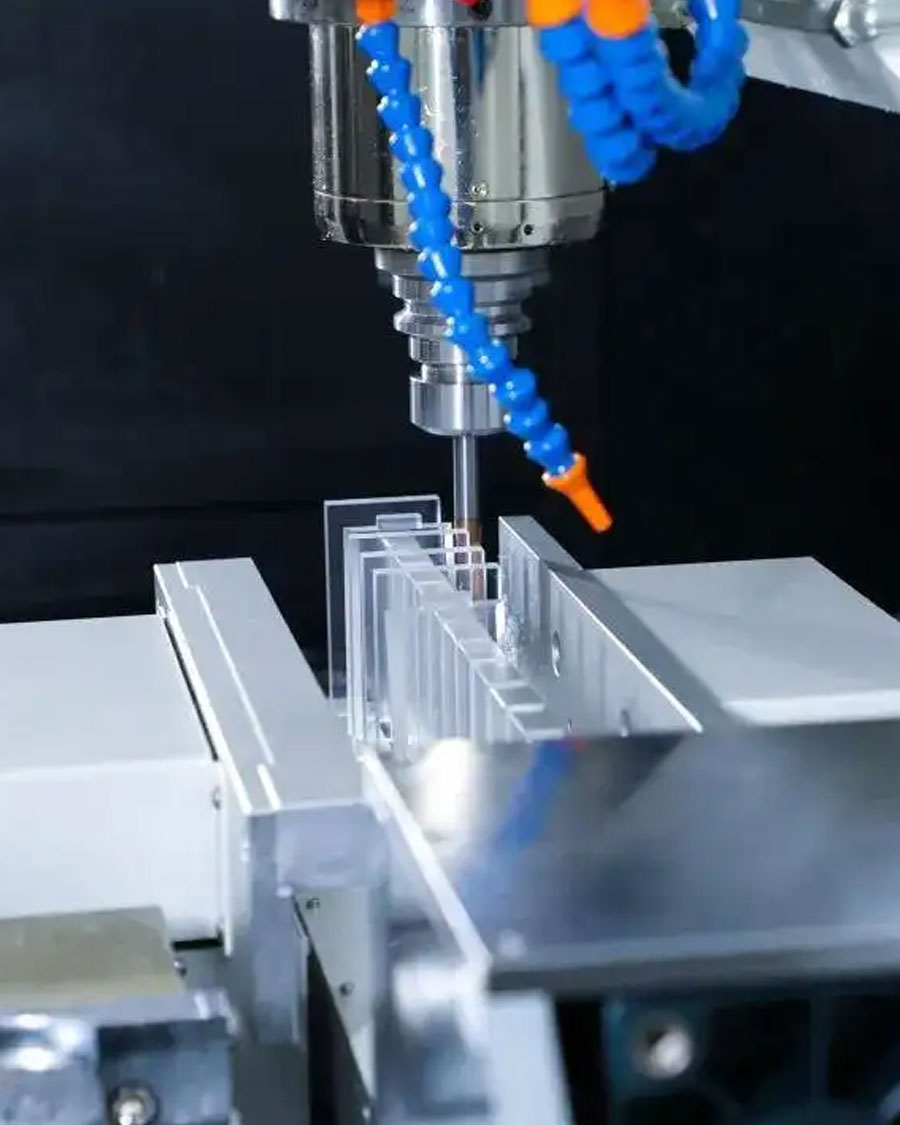

We provide high-quality precision machining services in China, which can provide you with more competitive prices and faster delivery cycle. Wonder Industries has high-precision three-axis, four axis and five axis CNC machine tools, constant temperature and humidity production workshops, online measurement systems, and ISO9001 quality management system. Wonder Industries has complete precision machining capabilities, including turning, milling, drilling, grinding, electric discharge, wire cutting and other processes.

- Whether it is metal materials or plastic materials, whether it is prototype or mass production Wonder Industries can meet your needs.

- We have the cnc machining capacity with the highest precision of 0.002mm, and can provide a complete test report. You can trust us with the project.

What Is Precision Machining.

Precision machining refers to machining with a machining accuracy of 10 to 0.1 μm and a surface roughness of 0.1 μm or less. Precision machining needs to be completed through advanced CNC machine tools, mature processing technology and strict quality management system.

- Wonder has high-precision three-axis, four-axis, five-axis CNC machine tools, and is equipped with constant temperature, constant humidity production workshop, online measurement system, ISO9001 quality management system.

- Wonder provides high-quality precision machining services in China, which can provide you with more competitive prices and faster lead times.

How It Works.

Wonder has a high-precision CNC machine tool with a positioning accuracy of 0.0018mm, the maximum speed can reach 36000rpm, the minimum machining radius is R0.05mm, and the roughness is within Ra0.1μm.

- We are also good at using diamond tools for milling, turning, boring and other special processes, using PCD tools for mirror grinding and other special processes, which allows our machining accuracy to reach within 0.002mm, and the roughness to within Ra0.1μm, which is far beyond ISO2768 -f International high precision tolerance standard.

- Wonder has excellent precision machining capabilities, which can meet your strict requirements for product dimensional accuracy and surface roughness.

- Our Precision machining services are designed to complement our many other manufacturing and finishing capabilities, providing you with an all-encompassing and satisfactory solution for your product development project.

Why choose us?.

Wonder provides one-stop service from prototyping to mass production, and has been trusted by thousands of customers from more than 30 countries around the world. With advanced equipment, strong engineering capabilities, scientific Management system and thoughtful service awareness continue to create value for customers, and at the same time, we are proud of providing a better development platform for our employees.

- Wonder established in 2008 and we have been approved by a series of quality assurance system which released by authorized third party organization. Awarded ISO9001:2015 certification.

- We have quality inspection equipment such as Hexagon CMM, projectors, altimeters, spectrometers, roughness meters, profilometers, hardness testers, and three-dimensional scanning. To ensure every part from our company can meet your requirements perfectly.

You Design It, We Manufacture It!.

As one of the CNC machining manufacturing companies in China,Wonder can custom your required products based on your design drawing for any given project. Since we have full capabilities in creating on-demand parts, we can tell you how to combine suitable features into your products according to your final applications, all come with consistent cost-effective prices, good quality, and short lead-time.

- Our highly experienced engineers and machinists utilize best-in-class software, including SolidWorks, MasterCAM, AutoCAD, and Espirit CAM, to create 3D CAD models that satisfy the design for manufacturing (DFM) criteriaㅡwhich means we design parts for ease of manufacturing.

- We keep costs down without compromising the machined parts’ quality, accuracy, and precision.

- We are located in southern China’s Greater Bay Area and not too far from shipping ports, allowing us to provide you with rapid manufacturing services.

Wonder’s Precision Machining Material Options.

Metals And Plastics:

- Aluminum: 2021, 5052, 6061, 6063, 7075, etc.

- Steel: 303, 304, 316, stainless steel, tool steel, carbon steel, etc.

- Brass

- Copper

- Special alloys: Kovar, Invar, Inconel, Titanium, Mocu, etc.

- POM

- PTFE

- PC

- PEEK

- PET

- PEI

- PA6