CNC Turning

“CNC Turning is a material removal process.CNC Turning services are suitable for technical and specialist industries where precision and attention to detail matter.”

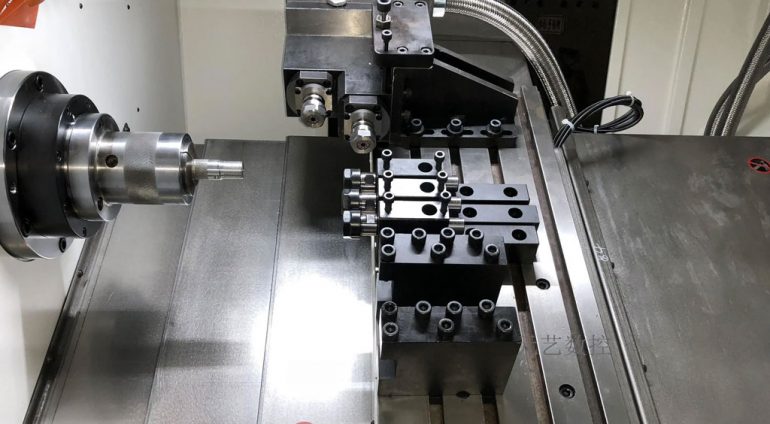

We offer high quality CNC turning services for many of our customers when it comes to delivering precision parts. Extremely accurate, CNC turning can be used to turn out thousands of components that are each identical. With minimal opportunity for human error, the services we offer give impeccable results, even when a demanding specification is required.

Capabilities up to 20″ round. We are able to produce high quality, close tolerance parts for needs ranging from rapid prototyping to high volume runs of machined parts. You can select the appropriate material for your applications, such as aluminum, copper, brass, stainless steel, titanium, plastic and more. If you are looking for a precision CNC Turning service, please contact us for more details.

CNC Turning China

You can create custom cnc turning service for your applications in China Wonder Company. We provide cnc turning almost anything you can draw, whether it is square, oval, triangular, trapezoidal, holes, curves shapes, geometric shapes, irregular shapes and more. We gladly accept a variety of drawings types including Step,SOLIDWORK,DXF, DWG, CDR, AI, PDF, and SVG, then send a competitive quotations to you. If you need mass production, in addition to the best price and we will provide free samples to old customer testing.

Prototype CNC Turning Services & Methods

At Wonder, we use several prototype custom cnc turning methods:

- Precision CNC Turning.More specific, these features are holes, grooves, threads, tapers, various diameter steps and even contoured surfaces.With precision cnc turning we achieve high tolerances and surface finishes.

- Swiss CNC Turning.CNC Swiss machine uses a bar stock that spins and slides through a guide bushing. This provides a powerful point of support, regardless of the length of the material in use. Turning tools are mounted to the face of the guide bushing and cut the stock near the bushing.

- Turn-Milling Machining.Eccentric forms or shapes that differ considerably from those produced by conventional milling or turning operations can often be turn milled. The method allows for high metal removal with superb chip control.

Advantages Of CNC Turning Parts

Prototype CNC Turning provides several benefits that make it suitable for a variety of applications:

- +/- 0.001” TOLERANCE:Typical tolerance, but can vary due to size & type of material.

- LIVE TOOLING:Performs up to 5 different CNC turning operations while in the lathe.

- 25” DIA X 80” WORK ENVELOPE:Suitable for long or large CNC turning parts and projects.

- Y-AXIS MILLING OPERATIONS:Expands the range of secondary operations, including simultaneous 5-axis milling/turning.

- ALL METALS/ALLOYS:Turn or machine all metals and certain types of plastics.

- MULTIPLE SPINDLE:Turn/mill a complete part in one setup, while maintaining feature relationships.

Contact Wonder for CNC Turning

Wonder is a precision CNC Turning parts machined supplier in China. With state-of-the-art CNC machines and skillful engineers, we can satisfy our customers’ requirements, and produce the CNC Turning parts from a prototype, low quantity to high volume production in good quality, competitive price and on-time deliveryand understands the specific methods for the best precision CNC Turning. We also maintain our machining jobshop with fully updated equipment that can properly machine Prototype materials.. So please feel free to contact us to quote your precision CNC Turning parts by our CNC Milling services.At Wonder, we can produce custom CNC Turning for nearly any application. If you would like to learn more about our CNC Turning capabilities, please contact us or request a quote today.