Magnesium Machining

Magnesium is the lightest structural metal and exhibits excellent machinability. There are many advantages to machining magnesium compared to other commonly used metals. Wonder can handle various magnesium alloy material projects that require high-precision and complex shape CNC machining parts, and provide extremely strict tolerances and excellent surface finish.

AVAILABLE MAGNESIUM VARIETIES

- Magnesium Alloy AZ91D

- Magnesium Alloy AZ31B

- Magnesium Alloy ZK61B

- Magnesium Alloy AM60B

- Magnesium Alloy AZ80A

Magnesium CNC Machining Methods

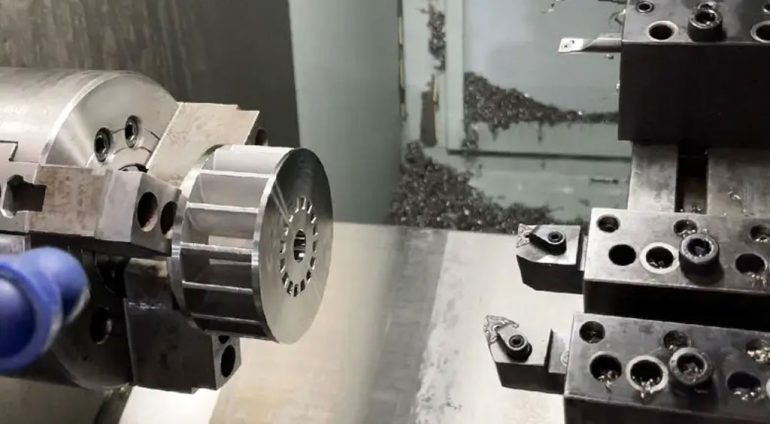

At Wonder, we use several Magnesium custom cnc machining methods:

- Magnesium CNC Machining: We are equipped with advanced 3-axis, 4-axis and 5-axis CNC machining centers, including high-speed CNC milling machines.

- Magnesium Die Casting: We use molds, which can provide cost-effective tools and accelerate the manufacturing cycle.

- Magnesium Parts Post-Treatment: Select from the metal surface treatment options to enhance parts, improve appearance and other benefits.

- Vacuum Welding: refers to the heating of magnesium parts in a vacuum chamber, which is mainly used for welding products with high quality requirements and easily oxidized materials.

- CAE Simulation Analysis: Complete the heat dissipation analysis of the natural conduction, fluid and composite modes of the overall chassis and components

Magnesium Machining Application – Reinforcement Industries

The Features Of Special Reinforced Chassis

The reinforced case is waterproof, dust-proof, rainproof, salt fog proof, shock vibration resistant, high and low temperature resistant, and has excellent electromagnetic compatibility.

It meets the requirements of GJB151A, GJB150, GJB322A and other relevant standards, and is suitable for harsh outdoor environments.

Customized Requirements

The structural design, appearance design, power supply design, electromagnetic compatibility analysis, heat distribution calculation and heat dissipation design of the reinforced chassis shall be carried out according to the customer’s requirements, meeting the requirements of the national standard.

At the same time, the supply chain with faster response speed can better respond to the demand of reinforced products for more customized magnesium alloy products.

Military Ruggedized Case

Wonder has long cooperated with special institutes and enterprises such as aerospace, science and engineering, China Special, electronic science and technology, and China shipbuilding. Our main business is to provide customers with reliable military cases and highly reliable liquid cooling solutions. Our purpose is to improve the reliability and stability of electronic equipment in extreme environments.

Magnesium Machining Application – Aviation Industries

Aviation Case Customization

Customized ATR aviation case, 19 inch 1U~6U aviation case, convenient CPCI, PXI, PXIE, VPX aviation case

Customized Requirements

It meets the requirements of national standards and is applicable to airborne, shipborne, vehicle borne, missile borne, ground station and other platform products with high mechanical structure strength and strong vibration impact resistance,

The chassis can adopt conduction heat dissipation and forced air cooling to ensure the normal operation of the equipment within the specified ambient temperature range

Excellent electromagnetic compatibility and anti-interference protection capability, meeting relevant requirements of GJB 151B-2013.

Magnesium Machining Application – Communication Industries

Machining Of Special Communication Shell

The products mainly processed and manufactured by the company include hand-held remote control and vehicle mounted transmitter; Communication control system receiver, communication control system on-board transmitter, robot intelligent communication on-board terminal, and MESH communication series product shell/box based on special intelligent communication.

Communication Housing Characteristics

The electronic communication housing/box is made of magnesium alloy materials processed by CNC machine tools, and can pass the environmental tests such as salt spray, mold and damp heat.

It has the performance of anti vibration, electromagnetic shielding, environmental protection, etc., and can make the equipment work normally under special environment. It is small in size, light in weight, simple in operation, and convenient to carry.

Magnesium Machining Application – Liquid Cooling Industries

Customization of liquid cooling system equipment

The company mainly processes and manufactures liquid cooling plates, temperature equalizing plates, cooling pipe temperature equalizing plates, case liquid cooling systems, and product shells and boxes of liquid cooling systems.

Characteristics of liquid cooling system

Through CAE performance analysis, complete the heat dissipation analysis of natural conduction, fluid, and composite modes of special machine case and components

Meet the installation and heat dissipation requirements of IGBT, CPU, GPU, SVG resistor, power amplifier and other electronic devices.

Excellent heat dissipation, good temperature equalization, low flow resistance, high mechanical strength and corrosion resistance.

Wonder has long cooperated with special institutes and enterprises such as aerospace, science and engineering, China Special, electronic science and technology, and China shipbuilding. Our main business is to provide customers with reliable military cases and highly reliable liquid cooling solutions. Our purpose is to improve the reliability and stability of electronic equipment in extreme environments.

Contact Wonder for Custom Magnesium CNC Machining

Wonder is a precision CNC Magnesium parts machined supplier in China. With state-of-the-art CNC machines and skillful engineers, we can satisfy our customers’ requirements, and produce the Magnesium CNC parts from a prototype, low quantity to high volume production in good quality, competitive price and on-time deliveryand understands the specific methods for the best precision CNC machining. We also maintain our machining jobshop with fully updated equipment that can properly machine Magnesium materials.. So please feel free to contact us to quote your precision Magnesium parts by our CNC machining services.At Wonder, we can produce custom Magnesium cnc machining for nearly any application. If you would like to learn more about our Magnesium cnc machining capabilities, please contact us or request a quote today.