1. Maintenance and maintenance of CNC lathe feed servo motor

For the servo motor of the CNC lathe, it needs to be maintained once every 10 to 12 months, and the machine tools with frequent acceleration or deceleration changes should be maintained once every 2 months. The main contents of maintenance are: use dry compressed air to blow off the dust of the brush, check the wear of the brush, if you need to replace, you need to use the brush with the same specifications, after replacement, you must run it with no load for a certain time to make it replace with Match with the surface of the device; check and clean the armature commutator to prevent short circuit; if equipped with a tachometer motor and pulse encoder, also check and clean. The DC servo motor in the CNC lathe should be inspected at least once a year, generally when the CNC system is powered off and the motor has been completely cooled; remove the rubber brush cap and unscrew the brush cover with a screwdriver knife Take out the brush; measure the length of the brush. If the brush of the FANUC DC servo motor wears from 10mm to less than 5mm, the brush of the same model must be replaced; carefully check the arc-shaped contact surface of the brush for deep grooves and cracks, and Is there any trace of ignition on the brush spring? If the above phenomenon occurs, it is necessary to consider whether the working conditions of the motor are excessively bad or whether the motor itself has problems. The compressed air without metal powder and moisture is introduced into the brush hole of the brush, and the brush powder adhered to the wall of the brush hole is blown off. If it is difficult to clean, you can use the screwdriver tip to clean it gently until the hole wall is completely clean, but be careful not to touch the surface of the commutator. The brush must be newly installed and the cover should be tightened. If a new brush is replaced, the motor should be run for a period of time to make the brush surface coincide with the commutator surface.

2.The maintenance and maintenance of the feedback components of CNC lathe measurement

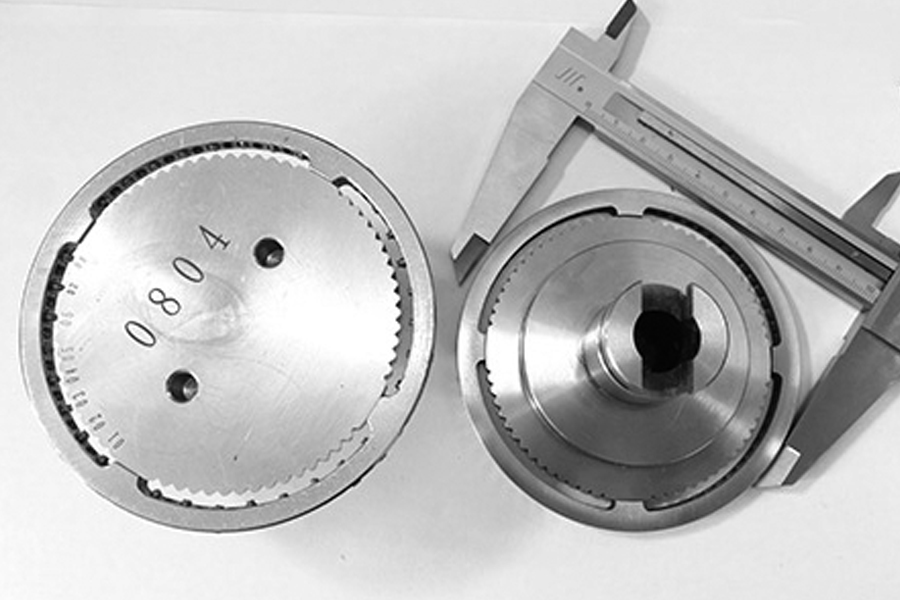

The detection element adopts more encoders and grating rulers, and also uses the same induction scale, magnetic ruler, resolver, etc. The maintenance electrician should check once a week whether the connection of the detection element is loose or contaminated by oil or dust.

3. Maintenance and maintenance of the electrical part of the CNC lathe

- ① Check whether the voltage value of the three-phase power supply is normal and whether there is any phase deviation, and if the input voltage exceeds the allowable range, adjust accordingly;

- ② Check whether all electrical connections are good;

- ③Check whether the various switches are effective, you can check the self-diagnosis screen displayed by the CNC system CRT and the programmable machine controller (PMC), LED indicators on the input and output modules to check and confirm, if they are defective, they should be replaced;

- ④Check whether the relays and contactors are working properly and whether the contacts are intact. You can use the CNC programming language to edit a functional test program, and run the program to confirm whether the components are intact and effective;

- ⑤Check whether the protection devices such as thermal relay and arc suppressor are effective, etc. The electrical maintenance on the power supply shall be carried out by the workshop electrician, and shall be checked and adjusted once a year. The door of the electrical control cabinet and the display of the operation panel should be sealed, and the temperature cannot be lowered by opening the cabinet door and cooling with an external fan. The operator should clean the dust filter of the electrical cabinet once a month, and check whether the cooling fan or air conditioner of the electrical cabinet runs normally every day.