The functions of the lathe tool holder in the CNC lathe for inclined bed are:

1. Function of CNC lathe tool holder for inclined bed

The tool holder on the machine tool is an important part of the tool. Many tool holders are also directly involved in the cutting work, such as the square tool holder on the horizontal lathe, the turret tool holder on the turret lathe, and the revolver cutter on the revolver turret lathe. Turret, turret tool post and balance tool post of automatic lathe, etc. These tool holders not only place cutting tools, but also directly participate in cutting and bear the great cutting force, so it often becomes a weak link in the process system. With the development of automation technology, there have been many changes in the tool holder of the machine tool, especially the automatic tool holder that uses electric (hydraulic) transposition on the CNC lathe, and some also use two rotary cutter heads. The machining center further adopts a tool magazine and a tool changer manipulator, and has established the functions of large-capacity storage tools and automatic tool exchange. The number of tools placed in this tool magazine ranges from tens to hundreds, and the time for automatic tool exchange is from Tens of seconds reduced to a few seconds or even a few seconds. This automatic tool changer composed of the tool magazine and the tool change manipulator has become the main feature of the machining center.

2. Type of CNC lathe tool holder for inclined bed

According to different tool changing methods, the tool holder system of CNC lathes mainly includes rotary tool holder, row tool holder and automatic tool changer with tool magazine. The following three types of tool holders are simple Introduction:

1. Row knife holder

The row type tool holder is generally used for small-sized CNC lathes, mainly for processing bar stock or disc parts. Its structure is as follows: the tool holders holding tools with different purposes are arranged on the horizontal slide along the X coordinate axis of the machine tool. This kind of tool holder is more convenient in terms of tool layout and machine tool adjustment. It can be combined with a variety of tools for different purposes according to the turning requirements of the specific workpiece. After a tool completes the turning task, the horizontal skateboard only needs to follow the program along the X axis After moving the pre-set distance, the second tool will reach the machining position, so the tool change of the machine tool is completed. This type of tool change is quick and time-saving, which is conducive to improving the production efficiency of the machine tool.

2. Rotary tool rest

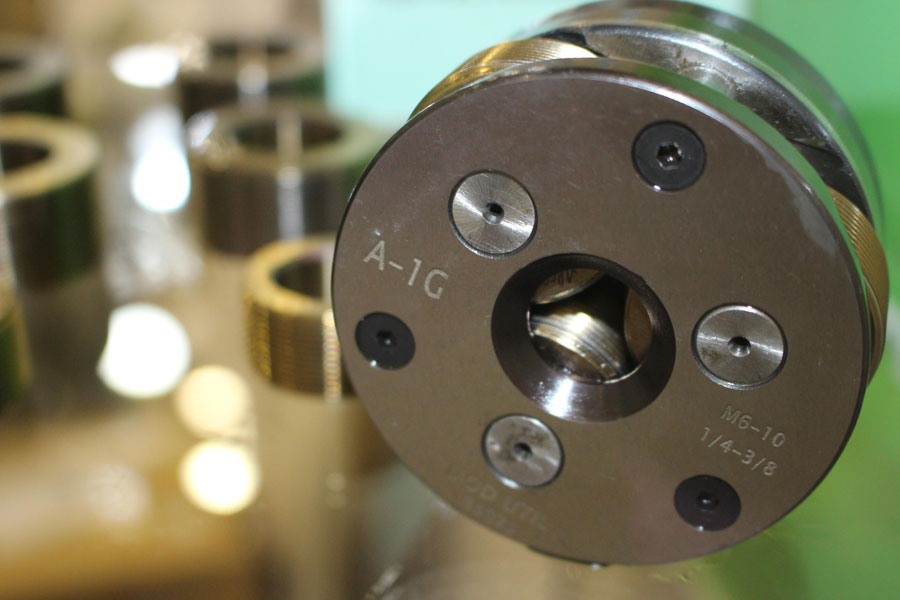

Rotary tool post is the most common tool change tool post for CNC lathes. The automatic tool change action of the machine tool is generally achieved through hydraulic system or electric. It can be designed into square, hexagonal tool post or disc type tool post according to the processing requirements. And install 4, 6 or more tools accordingly. The tool change action of the rotary tool holder can be divided into several steps, such as lifting the tool holder, indexing the tool holder, and locking the tool holder. Its actions are completed by the CNC system issuing instructions. According to the relative position of the rotary axis of the knife holder and the installation bottom, the rotary knife holder is divided into two types: vertical knife holder and horizontal knife holder.

3. Automatic tool changer with tool magazine

It is impossible for too many tools to be installed in the row-type tool holder and the rotary tool holder. Even if two tool holders are equipped, the number of tools is also limited. When a large number of tools are required for some reason, an automatic tool changer with a tool magazine should be used. The automatic tool changer with tool magazine consists of the tool magazine and the tool exchange mechanism.