The application and maintenance of CNC lathes must be indispensable. We must attach great importance to the maintenance and maintenance tasks of CNC lathes, especially for CNC lathe operators. maintenance.

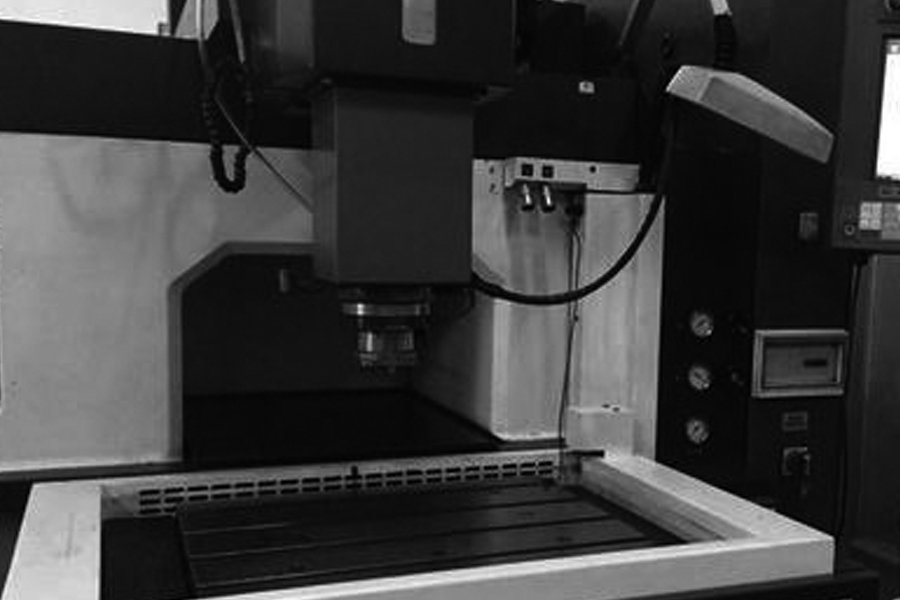

The use of CNC lathes is more difficult than the use of ordinary machine tools. CNC lathes are typical mechatronics products, which involve a wide range of knowledge, that is, the operator should have more professional knowledge of machinery, electricity, hydraulics, and gas; Furthermore, because the CNC system in its electrical control system is upgraded and updated relatively quickly, if you do not regularly participate in professional actual training and learning, you will not be able to master the new CNC piecemeal use. Therefore, the quality requirements of the operators are very high. To this end, it is necessary to stop the training of CNC operators, so that they can stop the lesser learning of machine tool principles, functions, smooth parts and methods, and lay the foundation for better use of machine tools. At the same time, in the application and management of machine tools, a series of practical and effective measures were formulated.

CNC lathes need to stop oil changing and maintenance. Because it is the same as your car, you must pay attention to the hygiene of the countertop in the future, so that dust and iron filings cannot enter the track. The disadvantages that come out in the future are poor accuracy and The feel becomes heavy and the operation is very heavy and laborious, so the CNC lathe should be changed once a month later, once every three months in the next year, and must be changed three times in the first three months. When the oil of the CNC lathe is changed, the impurities of the CNC lathe track will also increase. It will flow into the oil tank along with the new oil. It will not stay in the track and will not scratch the track.

CNC lathe maintenance “oil change” matters are as follows:

- 1. Check whether the coolant in the coolant tank is sufficient and not add it in time.

- 2. Check the liquid level of lubricating oil to ensure that the machine tool is smooth.

- 3. Check the oil level of the pneumatic triplet, which is about 2/3 of the height of the entire tubing. Every day, the water in the oil filter tank of the pneumatic triple unit is discharged by the drain switch.

- 4. Check the air pressure, hold the adjusting knob tightly, press the right-hand pressure to increase the pressure, and adjust the pressure by the left-hand pressure reduction guideline, the normal setting is 5-7kg / cm2. The pressure switch is usually set to 5kg / cm2. When the pressure switch is lower than 5kg / cm2, the alarm will appear. The “LOWAIRPRESSURE” alarm will appear piecemeal. After the pressure is reduced, the alarm message will disappear.

- 5. Check whether the air blowing of the cone hole in the spindle of the CNC lathe is normal, scrub the cone hole in the spindle with a clean cotton cloth, and spray light oil.