From the surface, the auxiliary device of the CNC lathe is similar to the indexing table of the general machine tool, but it also has its own characteristics in structure. It is mainly composed of transmission system, clearance elimination device and worm gear clamping device. It is mainly for circular feed movement; for indexing movement.

Differential indexing table is different from CNC rotary table, its function is to realize indexing motion, but the difference with rotary table is that indexing table can not realize circumferential feed. The movement of the indexing table is limited to specified angles, such as 90 degrees, 60 degrees, and 45 degrees. The indexing table guarantees its own high-precision requirements, so it must be used together with the positioning machine to ensure the safety of the machine tool.

The auxiliary devices of CNC lathes mainly include CNC indexing heads, automatic tool changers, and hydraulic and pneumatic systems. Of course, as a qualified CNC operator, you cannot forget to maintain them:

1. Automatic tool changer

Automatic tool changer is a characteristic structure of machining center that is different from other CNC machine tools. It has the function of automatically changing the required tools according to the processing technology requirements, to help the CNC machine tool save auxiliary time, and meet the requirements of completing multiple processes and working steps in one installation. Therefore, during operation, it is necessary to always check whether the operation of the mechanical structure of each component of the automatic tool changer works normally and whether there are abnormal phenomena; check whether the lubrication is good, etc., and pay attention to the tool change reliability and safety checks.

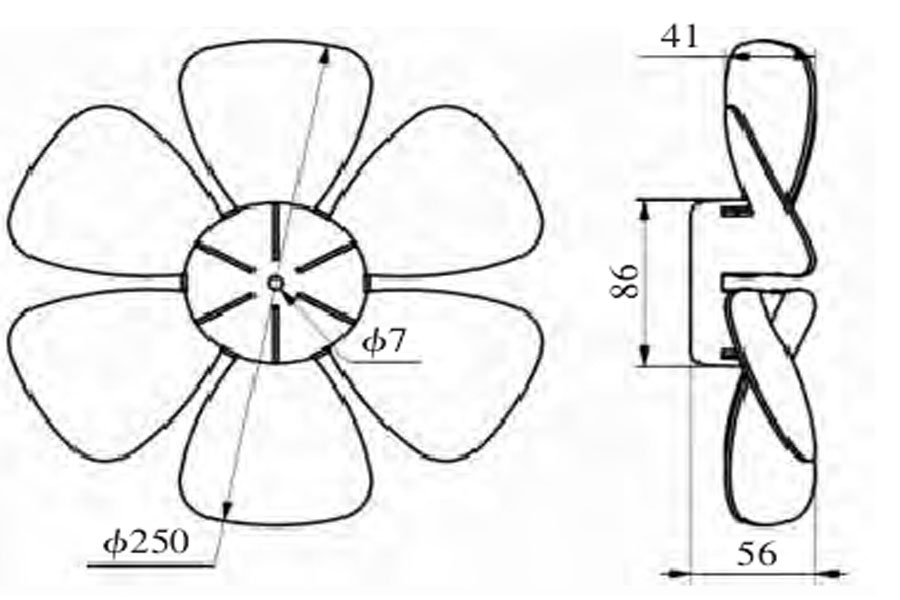

2. CNC indexing head

The CNC indexing head is a common accessory for CNC milling machines and machining centers. Its function is to perform rotary indexing or continuous rotary feed motion according to the instructions of the CNC device, so that the CNC machine tool can complete the specified processing accuracy. Pay attention to strictly operate and use in strict accordance with the requirements of the instruction manual and operation rules of the CNC dividing head.

3. Hydraulic system

- (1) Regularly inspect, filter and replace the oil in the oil tank;

- (2) Periodically check and clean or replace hydraulic parts, filter elements, and regularly check and clean oil tanks and pipelines;

- (3) Regularly check and replace seals to prevent hydraulic system leakage;

- (4) Check the performance of the cooler and heater, and control the oil temperature;

- (5) Strictly implement the daily inspection system to check whether the system leakage, noise, vibration, pressure, temperature, etc. are normal.

4. Air pressure system

- (1) Select a suitable filter to remove impurities and moisture in the compressed air;

- (2) Check the oil supply of the lubricator in the system to ensure that there is an appropriate amount of lubricating oil in the air to lubricate the pneumatic components, to prevent air leakage and component failure due to rust and wear

- (3) Maintain the tightness of the pneumatic system, regularly check and replace the seals;

- (4) Pay attention to adjust working pressure;

- (5) Regularly check and clean or replace pneumatic components and filter elements.