What is an angle head

The angle head is a machine tool accessory, originally produced in Europe, and has been widely used in various fields of mechanical machining such as aviation, automobile, and mold. By using the angle head, the machining range and adaptability can be increased without changing the structure of the machine tool, so that some machining that is difficult to complete by traditional methods can be realized, and repeated workpiece clamping can be reduced, and machining accuracy and efficiency can be improved. The angle head is mainly used in machining centers, can be installed in the tool magazine, and can be freely switched between the tool magazine and the machine tool spindle.

Because the angle head expands the performance of the machine tool, it is also called a universal angle head.

Type of angle head

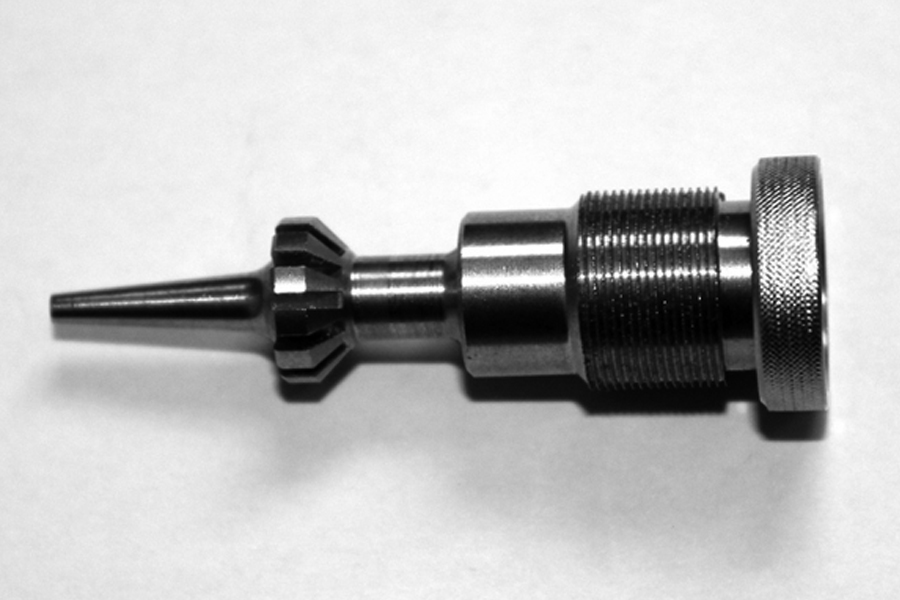

1.Single output angle head——This type of angle head is convenient to change tools and has high cutting rigidity. For deep hole machining, the water outlet function of the tool center can generally be realized.

2. Dual output angle head-This angle head adopts dual-axis output, which can better meet the machining requirements, solve the user’s troubles in the opposite direction, which requires manual adjustment of the angle head, and improve production efficiency.

3. Offset angle head-this angle head tool’s rotation centerline is not on the same plane as the machine tool spindle’s rotation centerline, so space is reserved for a certain direction (installation space, working space) in special machining occasions.

4. Adjustable angle head-The angle between the centerline of the tool’s rotation and the centerline of the machine tool’s spindle is adjustable. Unlike the above three types, it is fixed at 90 degrees. The adjustable angle range is generally 0 ~ 90 degrees, but there are special, such as the German mimatic angle head adjustable 0 ~ 98 degrees.

5. Non-standard angle head-customized.

Application of angle head

- When large workpieces are difficult to fix, when used in simple machining;

- Precision workpiece, fixed at one time, when machining multiple faces;

- When machining at any angle relative to the reference plane;

- The machining is maintained at a special angle for profiling milling pins, such as during ball end milling;

- When the hole in the hole, milling head or other tools cannot penetrate into the hole to process small holes;

- Oblique holes, chute, etc. that cannot be machined by machining centers, such as internal holes in engines and housing

- Other

Precautions when using angle head

- When the axis of the machining inclined hole is parallel to any one of the X, Y, and Z axes of the machine tool, the machine tool should have a linkage function of more than two axes before it can be used.

- When the axis of machining the inclined hole is not parallel to the X, Y, and Z axes of the machine tool, the machine tool should have more than three axes linkage function before it can be used.

- Before working, the head needs to be pre-run at 500 rpm for 10 minutes.

- Angle head working temperature is 50 degrees.

Angle head manufacturer

1. There are no domestic manufacturers focusing on manufacturing angle heads. Most of the cutting tool manufacturers focus on the production and development of angle heads. Compared with foreign products, there is still a considerable gap in quality and performance.

2. Many abroad, well-known German mimatic standard angle head series.