CNC high-speed precision parts processing mainly refers to the use of digital information recorded on the media to control the machine tool, so that it automatically performs the specified processing tasks.

CNC machining can ensure that the product achieves extremely high processing accuracy and stable processing quality; the operation process is easy to realize automation; high productivity and short production cycle; can greatly reduce the process equipment, adapt to the needs of rapid product replacement; it is usually closely connected with CAD Achieve the transformation of design ideas into the final product. Students should focus on the connection between processes and the significance of each step in the study of the entire CNC high-speed precision part processing process. Broadly speaking, the composition of the entire process includes product analysis-graphic design-process planning-path generation-path simulation-path output-processing-inspection. In this session, a specific case is completed by way of demonstration, focusing on understanding the connection of each link. The material processed in the case is two-color plate or plexiglass.

- 1. Product analysis Through product analysis, certain composition information and some specific processing requirements should be obtained.

- 2. Graphic design The graphic design should first be based on a detailed analysis of the product. For example, for the processing of seals, we must determine the font, text size, and type of seals through analysis and processing requirements.

- 3. Process planning Through the early analysis of the appearance and processing requirements of the workpiece product, each processing step is reasonably established from the overall processing.

- 4. Path generation The path generation process is actually that we implement the process planning through software, and at the same time optimize the tool path through parameter setting.

- 5. Path simulation After the path is generated, we generally have no intuitive feeling about its final performance on the machine tool. Here we can check the possible problems through path simulation, thereby reducing the scrap rate of actual processing. The general inspection focuses on the effect of the appearance of the workpiece, whether it is overcut or undercut, and then whether the process planning of the path is reasonable.

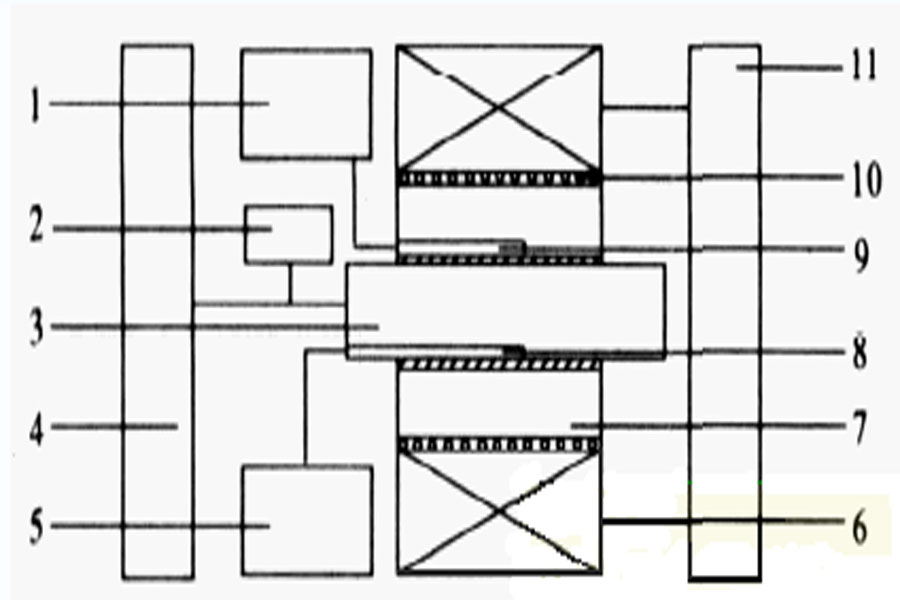

- 6. Path output Path output is a necessary step of software design and programming on the machine tool. Through the path output, the intermediate reference can establish a connection between the two. If the student has a CNC professional background, it can also be understood as post-processing of the tool path.