The machining center is a highly mechatronic product and the basic equipment of modern manufacturing industry, especially the mechanical processing industry, small mold manufacturing enterprises, engineering colleges, and technical schools. The demand for small machining centers is huge. It is of great significance to study the key technology of the machining center’s control principle, system design, debugging and fault maintenance, etc. to ensure the safe, reliable and efficient operation of the machining center.

This paper takes the actual factory project as the background and mainly completes the research, design and development of the electrical control system of the machining center. Based on the analysis of the technical requirements of the machining center, the paper designs and demonstrates the overall plan of the control system of the machining center; studies the key technologies in the process of realizing the functions of feed, spindle, automatic tool change, etc.

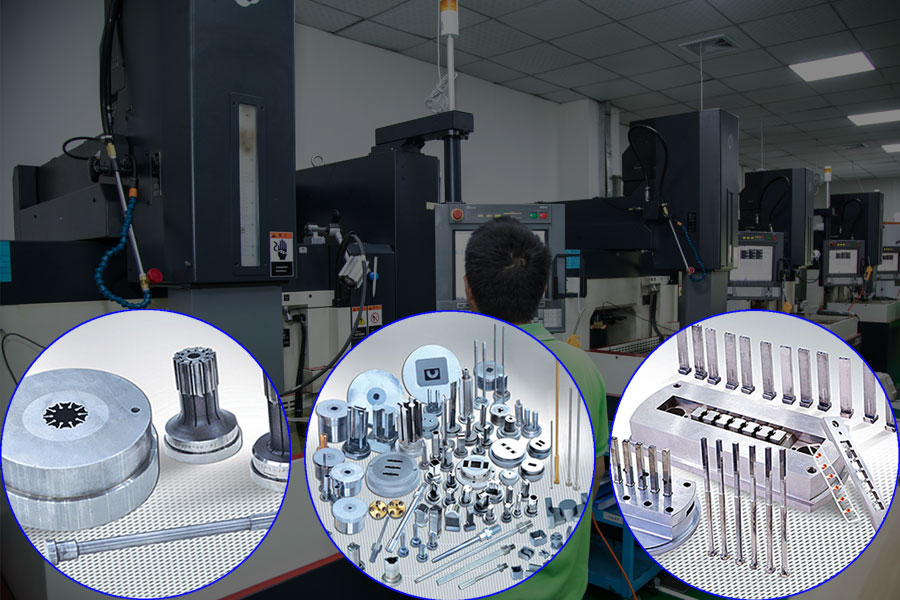

And design; put forward the configuration scheme of the servo motor and drive; design the hardware interface of the automatic tool changer / (ATC /) of the key components of the machining center and the PLC ladder control program; design the electrical control system of the machining center and study The DNC control scheme based on FANUC 0i system; expounds the debugging steps and methods of the system: analyzes the faults and problems that occur during the debugging of the system. Based on the research and design of this article, the TH5660 vertical machining center has been delivered to users. The actual operation shows that the system performance is stable, the human-machine interface is friendly, the operation is convenient, and the cutting accuracy of the parts meets the requirements of the drawings.