What are the eight characteristics of horizontal machining centers? The following editors tell you

- 1. The spindle of the CNC horizontal machining center is driven by a generous motor with large torque.

- 2. good cost performance, factory precision is compressed by 30% according to national standards, and it belongs to a precision processing center.

- 3. The indexing table is 1 × 360, and the spur plate is positioned for high positioning accuracy.

- 4, the tool changer adopts Taiwan tool magazine cam manipulator, with reliable performance and short tool change time.

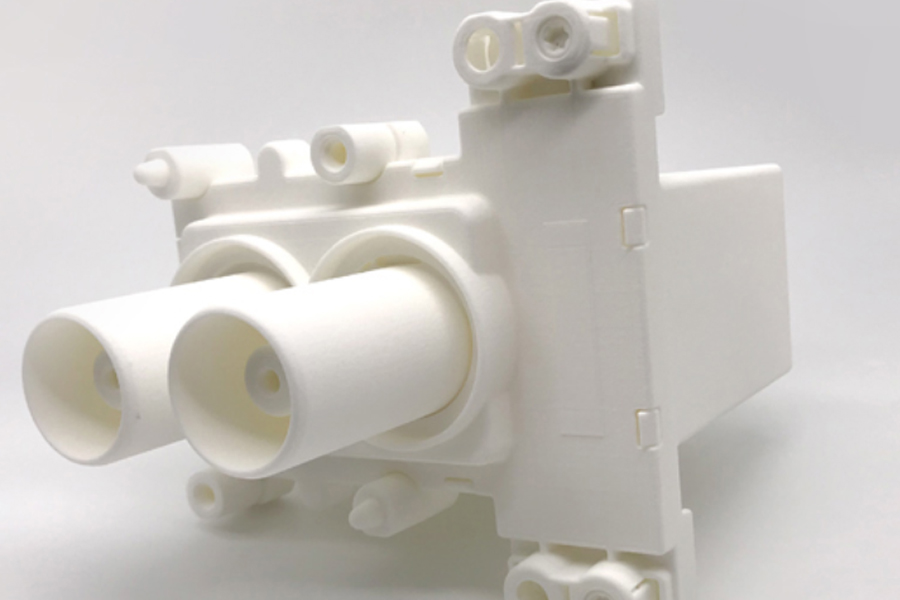

- 5, CNC horizontal machining center adopts three-dimensional modeling design, beautiful and elegant.

- 6, CNC horizontal machining center adopts inverted ‘T’ layout, the column moves, and the rigidity is good.

- 7. The guide rail of the NC horizontal machining center adopts the design principle of narrow and inclusive guide. The guide rail is hardened and ground, and the hardness can reach above hrc52. it is good.

- 8. The CNC rotary table is continuous indexing, adopting INA flat thrust radial ball bearings imported from Germany to ensure good transmission rigidity and optimized shock absorption performance, greatly improving the dynamic rigidity of the transmission system, which can achieve 15m / min Fast moving speed.

The above is the introduction of the eight characteristics of horizontal machining center, I hope to help everyone.