Many years of CNC machine tool maintenance experience confirms that in the total number of faults, faults caused by power supply account for a considerable proportion. Many of the CNC machine tool power failures belong to the device damage that the machine tool users have the ability to eliminate by themselves, and their field has already belonged to the chip-level repair [1].

The power supply of CNC machine tools is divided into three levels, from primary power to three powers, which are derived relationships in turn, and the frequency and difficulty of failures caused by them are also increased in turn. The specific classification is as follows:

(1) Primary power. The primary power is the three-phase 380 V power supplied by the power grid of the workshop, which is the total energy supply for the work of the CNC machine tools. The power supply is required to be stable, the general voltage fluctuation range should be controlled between 5% to 10%, and no high-frequency interference.

(2) Secondary power. Derived from a three-phase power source via a transformer. Its main uses are:

1) The derived single-phase AC 220 V and AC 110 V are used to supply power to the CNC unit and the display unit as power sources for heat exchangers, machine control circuits and switching power supplies.

2) Some CNC machine-derived three-phase low-voltage DC 24 V rectifier bridge block power supply. Some CNC machine tools generate a three-phase AC 220 V by a three-phase transformer, which is supplied to the servo amplifier power module as its working power.

(3) Three power supplies. The tertiary power is a variety of DC power used in CNC machine tools, it is converted from the secondary power. There are mainly these:

1) The DC voltage provided by the servo amplifier power component and the servo amplifier component are inverted into three-phase AC power with variable frequency and voltage amplitude to control the speed of the AC servo motor.

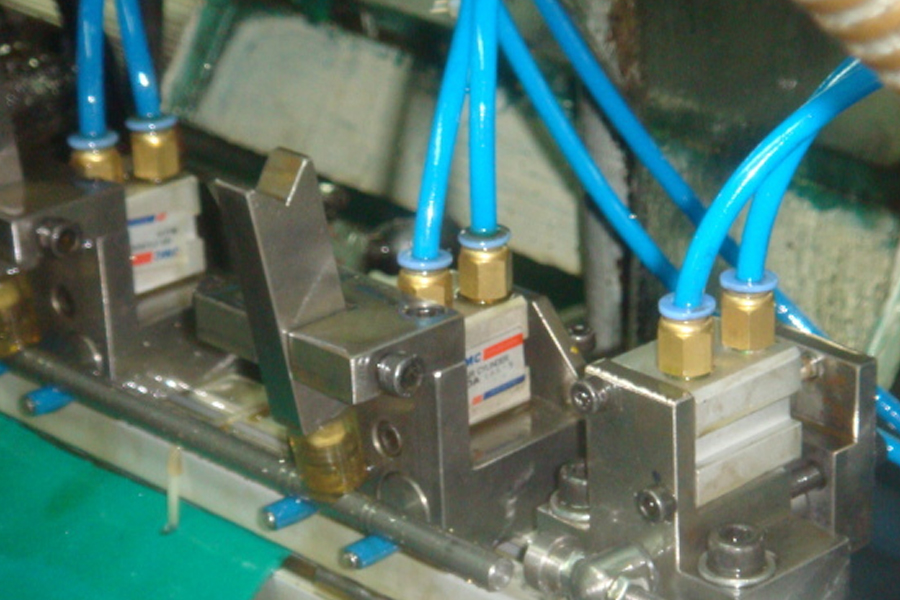

2) The AC 24 V provided by the rectifier bridge block is used as the “ready” and “controller enable” signal source for the solenoid valve of the hydraulic system, the power source of the motor brake solenoid and the servo amplifier unit.

3) The low voltage DC voltage provided by the switching power supply or DC / DC power module. These voltages are: +5 V, ± 12 V, ± 15 V, which are used as the power supply for measuring grating, CNC unit and electrical unit of servo unit.

3 Components used in the power circuit of CNC machine tools The components used in CNC machine tools from primary power supply to third power supply are:

(1) Workshop power distribution devices generally include: a three-phase AC voltage regulator and a circuit breaker (also known as an air switch, or a knife switch) connected to the power grid of the workshop.

(2) Machine tool components, including: filters, reactors, three-phase AC transformers, circuit breakers, rectifiers, fuses, servo power components, DC / DC modules and switching power supplies.

4.Power failure instance analysis

(1) PLC does not work if the power grid fluctuates too much. Appears as no output from the PLC. First check the input signals (power signal, interference signal, command signal and feedback signal). For example, the CNC lathe using SINUMERIK 3G-4B system, its built-in PLC can not work. Using the observation method, first check the voltage waveform of the power grid with an oscilloscope and find that the power grid fluctuates too much and the duration of the undervoltage noise transition is> 1s (external cause). As the machine tool is in the debugging stage, component faults in the power system should be excluded. From the internal anti-grid interference measures (filtering, isolation and voltage stabilization), it can be known that the conventional power system can no longer cut off or filter out the undervoltage of the power grid that has lasted too long Noise, which is caused by insufficient anti-grid measures (internal cause), causing the PLC to fail to obtain normal power input and cannot work. Add an AC voltage regulator to the system power input, and the PLC works normally.

(2) Power failure. For a double-station CNC lathe, each station is controlled by a separate NC system. The NC system uses the Siemens SINUMERIK810 / T system. The NC system at the right station often shuts down when the automatic processing of parts is interrupted. After restarting the system, the NC system can still work automatically. Check the 24 V power supply load and there are no short-circuit problems. Analyzing the pattern, two NC systems share a 24 V rectified power supply. There may be two reasons for this failure:

1) The power supply quality is not high, the power supply fluctuates, and the faulty NC system has more sensitive power requirements.

2) The problem of the NC system itself, the system is unstable. According to this judgment, first monitor the 24V power supply voltage and find that its voltage amplitude is low, only about 21V. It was found that at the moment of failure, this voltage floated down, and immediately after the NC system was powered off, the voltage rose back to about 22V. The faults usually occur when the spindle starts. The reason may be that the 24V rectifier transformer has a problem, the capacity is insufficient, or the inter-turn short circuit makes the rectifier voltage low and the grid voltage fluctuates, affecting the normal operation of the NC system. In order to determine the cause of this failure, the AC stabilized power supply was used to increase the AC 380V supply voltage to 400 V, and this failure did not occur again. For this reason, the 24V rectifier transformer was replaced, and the problem was completely solved.

(3) For a PNE480L CNC lathe manufactured by VDF.BOEHRINGER (Germany), when the CNC system is turned on by turning on the main switch, all the indicators are on except that the READY lamp is off. The CNC system of this machine is Siemens SYSTEM5T system. Because the fault occurs at the moment of power-on, you should check whether the power-on clear signal RESET is abnormal. And because the DP6 light on the motherboard is on, and the DP6 monitors the related DC power supply, it is necessary to check the relevant circuits driving the DP6 and the related DC power supply. The steps are as follows: Because the DP6 light is an alarm display, first check the relevant circuits of DP6. After inspection, it was confirmed that the logic state of the bi-stable flip-flop LA10 driving DP6 is incorrect and damaged. After the replacement with new parts, although the DP6 indicator is off, the failure phenomenon still exists, and the CNC box cannot be started. Check the * RESET signal and the connections of the connectors in the CNC box are good, but the * RESET signal is abnormal, and it is found that the logical relationship between LA01 at the A38 position and the NOT gate circuit is incorrect. Then check each DC current. Checking ± 15V, ± 5V, ± 12V, + 24V, it was found that the voltage was -5V to 4.0V, and the error was more than ± 5%. Further inspection revealed that the printed circuit board copper foil was broken at the solder foot of a large filter capacitor C19 behind the circuit rectifier bridge. After welding it, the voltage is normal, the logic relationship of the LA01 circuit and the * RESET signal are correct, the fault is removed, and the CNC box can start normally.

(4) The reference point return is abnormal. This is because when returning to the reference point, the conditions of “must be in the direction of returning to the reference point, not too close to the reference point (more than 128 pulses), and the progress of returning to the reference point cannot be too low” are not met. The processing steps for this type of fault are [2,3]:

1)> 128 pulses from the reference position, and returning to the reference point.

① The motor rotates less than 1 revolution (that is, it does not receive a signal of 1 revolution). At this time, first change the starting position when returning. Under the state of position deviation> 128 pulses, perform more than 1 revolution in the direction of returning to the reference point. The rapid traverse of the motor is used to detect whether a 1-turn signal has been input.

② The motor has rotated more than 1 turn. This is a separate pulse encoder. At this time, check whether the 1-turn signal of the pulse encoder is input to the axis card when the position is returned. If it is, the axis card is defective. If it is not input, first check whether the power supply voltage for the encoder is low (allow voltage fluctuation Within 0.2V), otherwise the pulse encoder is defective.

2) <128 pulses from the reference position.

① Check whether the feed speed command value, rapid traverse override signal, reference point return deceleration signal and external deceleration signal are normal.

② Change the starting position at the time of return so that the position deviation exceeds 128 pulses.

③ The speed of returning to the reference point is too low. The speed must be a speed with a position deviation of more than 128 pulses. If the speed is too low, the 1-rotation signal of the motor is scattered, and correct position detection is impossible.

(5) A machining center is equipped with F-0M system, and the tool magazine and worktable rotate at the same time during automatic operation. After resetting, adjusting the tool magazine and the workbench, it works normally. However, when the machine was restarted after power failure, servo alarm No. 410 appeared on the CRT. Check that both the L / M axis servo PRDY and VRDY indicators are on; the feed axis servo power supply AC100V and AC18V are normal; the PRDY indicators on the x, y, and z servo units are off, and the three MCCs are not activated; The voltage on it was found to be abnormal at 24V, ± 15V; the resistance of the power fuse on the axis servo unit was too large. After replacement, the DC voltage returned to normal, and the machine tool was re-run, and the alarm No. 401 disappeared.

(6) Failure phenomenon: a company produces a VF2 vertical milling machining center. After the machine has been running for one year and seven months, alarm No. 161 (x-axis over current or drive fault) appears during processing, and the machine stops running. The alarm can be cleared with the “RESET” key, and the machine can resume operation. This fault phenomenon occurs occasionally. After two years of running the machine with a disease, the frequency of faults increases, and a failover phenomenon occurs: even when the reset key is used to clear alarm 161, the alarm information is reported to No. 162 (Y-axis over current or drive fault ), If cleared again, report the z-axis again, and so on. The machine can no longer run.

Fault analysis and inspection: According to the fault alarm information, the phenomenon is transferred between several servo axes. It is not difficult to see that the fault occurred in the public link related to each servo axis, that is, it is the “position control board” of the CNC unit or the servo unit. A power supply component has failed. Position control board is one of the numerical control unit components. According to empirical analysis, the probability of failure of the electrical unit of the numerical control unit is very low, so analyzing and checking the servo power supply component is a more feasible troubleshooting entry point. The inspection found that the machine tool’s servo power was divided into two parts, of which the output of low voltage DC ± 12 V was the switching power supply. The measurement results are: +11.73 V, -11.98 V. Analyzing this result, the positive voltage output was 0.27 V lower, and the voltage reduction range was 2.3%. Due to the lack of a quantitative concept, it is assumed that this switching power supply is faulty when no other source of fault is found temporarily. Troubleshooting: In order to verify that the output voltage deviation is the root cause of machine tool failure, replace the original power supply with a WYJ type dual transistor DC voltage regulator, adjust the two output voltages symmetrically, and adjust the amplitude to 12V. After the machine is turned on, the machine alarms. disappear. In the test operation of the next 20 working days, the failure no longer recurs. It is fully confirmed that the failure is caused by the damage of this servo power supply component. Theoretical analysis [4]: Some operational amplifiers and comparators are powered by a single power supply, and some are powered by dual power supplies. Op amps with dual power supplies require positive and negative power supply symmetry. The difference cannot be greater than 0.2 V (operation (Except for playback), otherwise it will not work properly. And this faulty power supply, the two output voltages differ by 0.25 V, which is beyond the allowable range of the error, which is the root cause of the fault.

5.Conclusion

Through the above fault examples, it is not difficult to see that the abnormality of the power supply of CNC machine tools is sometimes not obvious, and sometimes only the deviation is less than 0.3 V, but it causes the machine tool failure. Therefore, in the maintenance, we must summarize the maintenance experience in this area to improve the efficiency of machine tool failure maintenance.