1. Whether the CNC machining center processes iron parts is good or hard rail

Iron parts are relatively common workpieces. Many customers will ask “Is the CNC machining center processing iron parts good for hard rails or wire rails?” When they have not used a machining center to process iron parts. This question is indeed a twist on many CNCs. For customers who are not familiar with the machining center, Taicheng CNC will answer this question for everyone today.

Before analyzing the specific use of hard rail or wire rail, first as a CNC machining center manufacturer, you must ask the customer what kind of iron parts to be processed, how big and small, whether it is to finish or rough machining, and other details. Without understanding these details, even as a manufacturer specializing in the production of CNC machining centers, it is not possible to give an accurate answer. Generally speaking, the iron parts we usually say are relatively large workpieces. Of course, special cases are not ruled out, then we will use the iron parts with larger sizes.

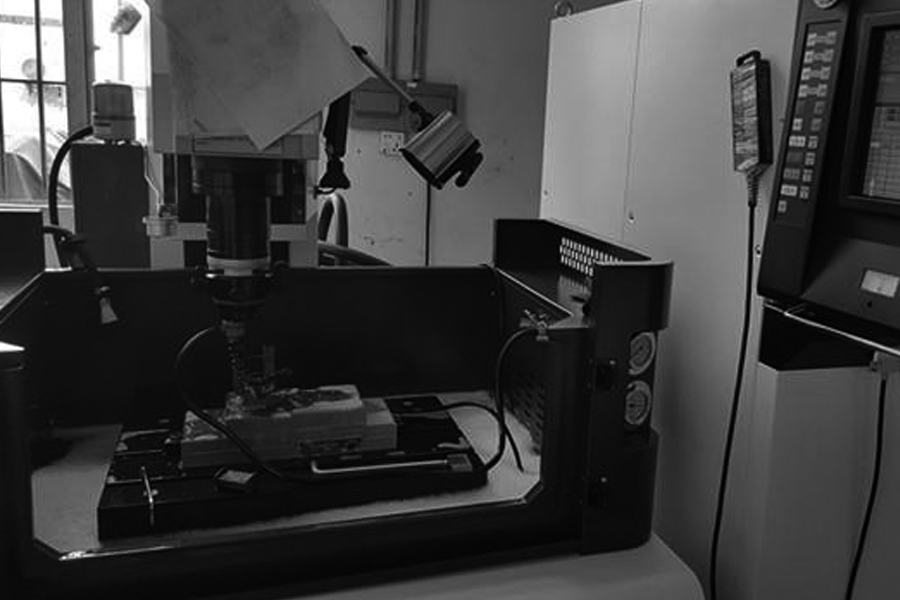

Large-size iron parts are of high quality and generally have a large amount of cutting. In this case, the hard rail is the most suitable. The hard rail has good rigidity, strong earthquake resistance, and strong load bearing capacity, which is suitable for heavy-load cutting. If you use a wire rail CNC machining center, it is not very good, or even damages the guide rail. The wire rail is likely to deform due to the heavy load cutting. Therefore, unless customers have special requirements, our CNC machining center manufacturers generally recommend that customers use hard-track CNC machining centers, and the same type of CNC machining center hard rail is cheaper than the linear rail, and the CNC machining center with a large stroke such as VMC1270, etc. are not available with line rails, because these large-stroke CNC machining centers are generally used for heavy-duty cutting.

2, where is the CNC machining center hard track better than the line track

The advantages of hard rails are also mentioned a little above, high rigidity, good seismic resistance, and strong load bearing capacity. These advantages come from the structure of hard rails. The hard rail CNC machining center is a CNC machining center that integrates the guide rail and the bed. The guide rail is cast on the bed. This structure is much more rigid than the linear rail CNC machining center using ball or ball guide rails, but it has a slight deficiency in processing accuracy and production efficiency, but the linear rail CNC machining center It is too easy to damage when it is used to process large-sized iron parts.