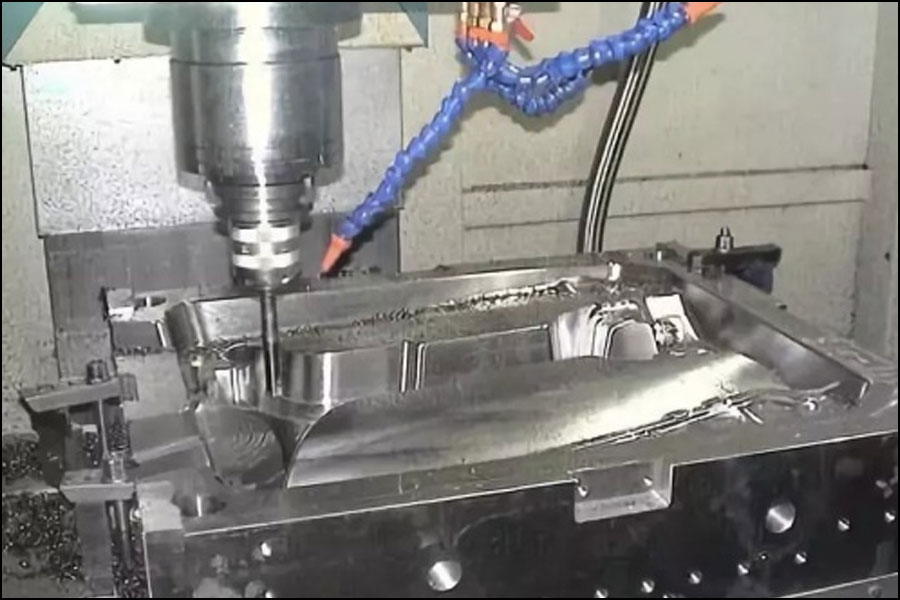

With the rapid development of science and technology, the application of metal electromachining has become more and more widespread, especially in the manufacture of molds. Electro-metal machining can be applied to many process specifications. For example: forming the cavity of complex parts, cutting metal, strengthening the surface of parts, etc.

The most basic advantage of this method is that it can process any conductive material and alloy, regardless of its hardness and other mechanical properties. This makes it possible to process hardened metals and is also suitable for machining hard alloys.

Electro-metal machining mainly exerts advantages in manufacturing molds and some special-shaped parts. Wire-cut EDM machine tools can also be controlled by programs, and the manufacturing precision of parts is also high. In this way, the structure of the mold is simplified, greatly reducing the labor intensity of the mold fitter, and also improving the product quality.

Protection Technology in Electromachining

(1) Protection against harmful gases

During electromachining, a very high temperature is generated, which instantly melts the metal. Because it is processed in kerosene or motor oil, the gas and steam of the liquid medium continuously released in the air forms bubbles to float on the surface of the liquid. When these bubbles burst at different distances from the tool electrode, and become numerous smoke rising and scattered, these bubbles contain metal minerals. For example, when electromachining in kerosene, the air is polluted by kerosene vapors and oxides (carbon monoxide and carbon dioxide). In addition, metal mineral dust is emitted.

The dust formed during the electro-machining process is mainly particles of various sizes and shapes that are separated from the processed metal, tool electrode materials, and kerosene or motor oil during combustion. A small part of dust is scattered on the liquid surface together with air bubbles, and most of the dust is deposited on the bottom of the oil tank, so it needs to be removed regularly.

To eliminate harmful gases, local ventilation must be provided. It is the most effective way to exhaust the hood at the edge of the oil tank.

(2) Protection of the epidermis from liquid media

When machining parts are installed in the oil tank using liquid medium, when removing the machining parts from the machine tool and cleaning the oil tank, the liquid medium will contact the workers’ hands, so that the skin pores are easily contaminated by the eroded metal dust, which weakens the elasticity of the skin. And fine cracks appear.

In order to protect the skin from cracks and prevent metal dust from penetrating into the skin pores, hands must be coated with protective ointment to protect the skin.

On-line cutting machine tools have used emulsion instead of kerosene as the liquid medium.

Safe operation of electric machining machine tools

I vår butik säker, kan en effektiv, även den dagliga dosen av Kamagra innehåller Levitra. För de flesta männen sida träder effekten i kraft efter 30-60 minuter efter intag, eftersom det inte kräver mycket planering.

- Wear work clothes, tight cuffs or sleeves when working. Lesbians should wear work hats with their hair tucked into their hats.

- After starting up, check whether the voltage, oil pressure and the indicated value of each instrument are normal. Otherwise, the electrician should be rectified in time.

- Turn off the power when loading or unloading the workpiece.

- Do not touch the workpiece with your hand or conductor during machining. Do not touch switches or other electrical parts with wet hands.

- When pumping oil, pay attention to the index of the vacuum gauge, and do not exceed the rated voltage of the vacuum, so as to prevent the oil pipe from exploding.

- Smoking and other open flames are strictly prohibited in the operating room. Fire extinguishers should be available around.

- In the event of a fire, immediately cut off the power supply and use carbon tetrachloride or dry powder and dry sand to extinguish the fire. Water and foam fire extinguishers are strictly prohibited, and the fire brigade should be reported to the rescue in time.