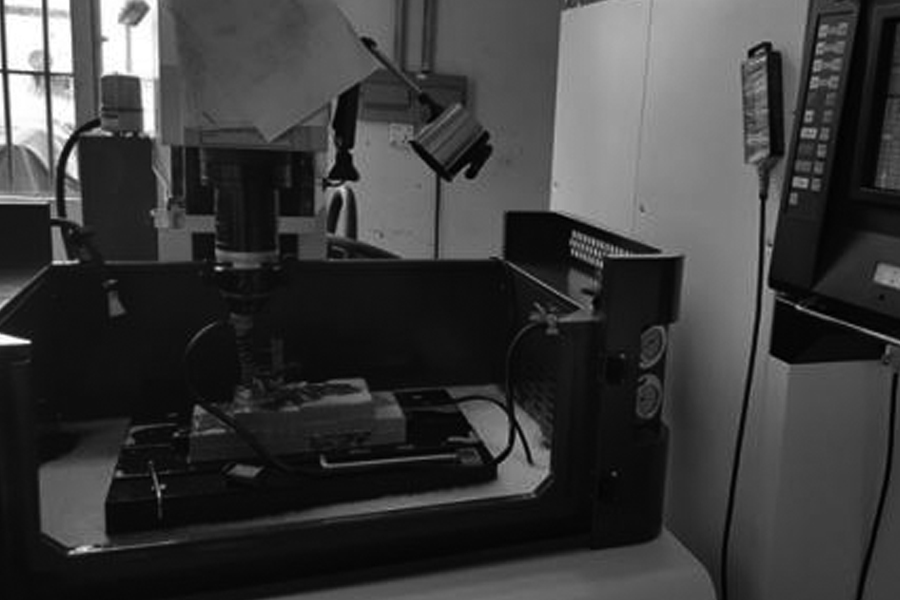

The CNC lathe is mainly composed of seven parts: processing program, input device, CNC system, servo system, measurement feedback device, auxiliary control device and machine tool.

The machining principle of the CNC lathe must first digitize the pattern and process information of the machined parts, write the machining program with the prescribed code and program format; then enter the programmed instructions into the CNC device of the machine tool; then the CNC device will program ( Code) After decoding and calculation, it sends signals to the servo mechanism and auxiliary control device of each coordinate of the machine tool to drive the moving parts of the machine tool to control the auxiliary movement required, and finally produces qualified parts.

Some failures will inevitably occur in CNC lathes, and they are divided into destructive failures and non-destructive failures according to the degree of damage when the failure occurs:

1. Non-destructive failure

Most of the faults of CNC lathes belong to this type of fault. When the fault occurs, it will not cause any harm to the machine tool and the operator. Therefore, when diagnosing this type of fault, the fault can be reproduced, and the fault phenomenon can be carefully observed and the fault can be analyzed through the fault phenomenon. And diagnosis.

To deal with different kinds of faults of CNC lathe roots, we must first analyze clearly and then find out the countermeasures.

2. Destructive failure

Such failures can cause injury or damage to the operator or equipment, such as over-travel, speeding, component collision, etc.

Example analysis: If a CNC lathe is under normal processing, the tool hits the workpiece, causing significant losses. After careful analysis, it is found that the reference point return is wrong, and the position of the travel switch (stop) and the electronic grid are carefully analyzed. The coincidence of positions (occasionally) causes an additional electronic grid to be fed in the Z direction, thereby causing a destructive failure of the collision between the tool and the workpiece. This phenomenon can move the position of the travel switch, and the problem can be solved satisfactorily.