Principle of mold thimble arrangement

- The ejector pin should be arranged so that the ejection force is as balanced as possible. The demolding force required for complex structures is large, and the number of ejectors should be increased accordingly.

- The thimble should be set in effective parts, such as bone, column, steps, metal inserts, and some thick structural parts. The thimbles on both sides of the bone and column should be arranged as symmetrically as possible, and the distance between the sides of the thimble and the bone and column is generally D = 1.5mm. In addition, try to ensure that the center line of the thimble on both sides of the column passes through the center of the column.

- Avoid setting up thimbles across steps or on inclined surfaces. The top surface of the thimble should be as smooth as possible, and the thimble should be arranged at the structural part where the rubber parts are better stressed.

- A flat thimble should be used when the plastic part is deeper (depth ≥20mm) or it is difficult to arrange a dome needle. When using a flat thimble, use an insert as much as possible at the flat thimble to facilitate cnc machining.

- Avoid sharp steel and thin steel, especially the top surface of the ejector pin should not touch the front mold surface.

- The arrangement of thimbles should consider the side distance between the thimbles and the water conveyance channel to avoid affecting the processing and water leakage of the water conveyance channel.

- The ejector function of the ejector is taken into consideration. In order to exhaust the ejector, ejector should be arranged at the place where the vacuum is easy to form.

- For plastic parts with appearance requirements, the ejector pin cannot be arranged on the appearance surface, and other ejection methods shall be used.

- For transparent plastic parts, the thimble cannot be placed on the part that needs to transmit light.

The selection principle of the mold thimble

- Use a large diameter thimble. That is, if there is enough ejection position, a larger diameter and size-first ejector should be selected.

- The size of the thimble should be as small as possible. When selecting a thimble, the size of the thimble should be adjusted to minimize the size specifications, and the preferred size series should be selected as far as possible.

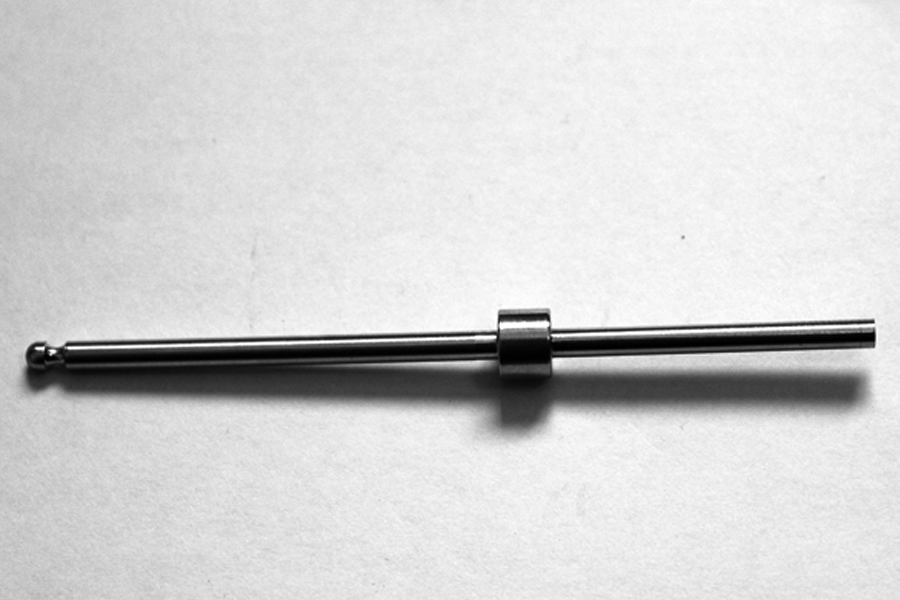

- The ejector used should meet the ejection strength requirements. During ejection, the ejector pin must withstand large pressure. To avoid bending and deformation of the small ejector pin, when the ejector pin diameter is less than 2.5mm, an ejector pin should be used.