Core abstract: Solution treatment is to heat the die casting to a high temperature, keep it at this temperature for a long time, and then rapidly cool it to make the product dissolve to a large extent, which can improve the strength and plasticity of the casting and increase the corrosion resistance of the alloy casting.

What are the main aspects related to the effect of solution treatment

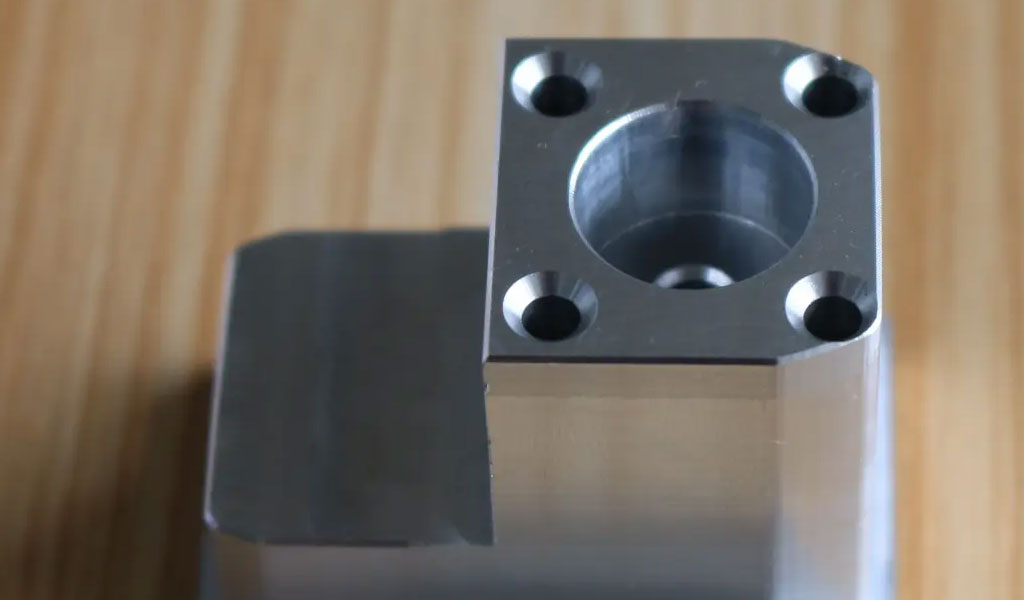

Solution treatment is to heat the die casting to a high temperature, keep it at this temperature for a long enough time, and then cool it quickly to make the product dissolve to a large extent, which can improve the strength and plasticity of the casting and increase the corrosion resistance of the alloy casting. So what are the main aspects related to the effect of solution treatment?

- The holding time is determined by the dissolution rate, which is also related to the type of alloy, composition, structure, casting method and the shape and thickness of the casting.

- The faster the cooling speed is, the higher the mechanical properties of the casting are, and the greater the possibility of casting deformation is. Therefore, many castings are cooled in hot medium.

- The higher the temperature of solution treatment, the faster the dissolution rate will be and the better the effect will be.

The solution effect of aluminum alloy die castings is mainly due to the above three points. It is easy to produce thin burrs in the process of manufacturing finished products, which has an impact on the appearance and quality of the products. The Wonder industry frozen deburring machine can remove burrs without damaging the surface of the products. For products with smaller volume, thousands of burrs can be made every six or seven minutes, which is highly efficient and saves factory costs.