The tensile elastic modulus is the ratio of the stress to the strain (ie, the distance) generated by the specimen in the elastic range. It is one of the indicators to characterize the tensile properties of materials. The larger the value of tensile elastic modulus, the greater the rigidity and the higher the strength. Also called Young’s modulus, it is expressed by E.

The formula for calculating the tensile modulus is as follows:

E = Δf / Δh

Among them, Δf represents the change in stress between two points per unit cross-sectional area, and Δh represents the change in strain between the two points.

The current methods for accurately measuring the tensile elastic modulus include the extensometer method and the strain gauge method.

Extensometer method

Extensometer is an instrument used to measure the line deformation between two points where the measurement part is in contact with the sample. It usually consists of three parts: a sensor, an amplifier and a recorder. It can be divided into four categories: mechanical extensometer, optical extensometer, electromagnetic extensometer and resistance extensometer.

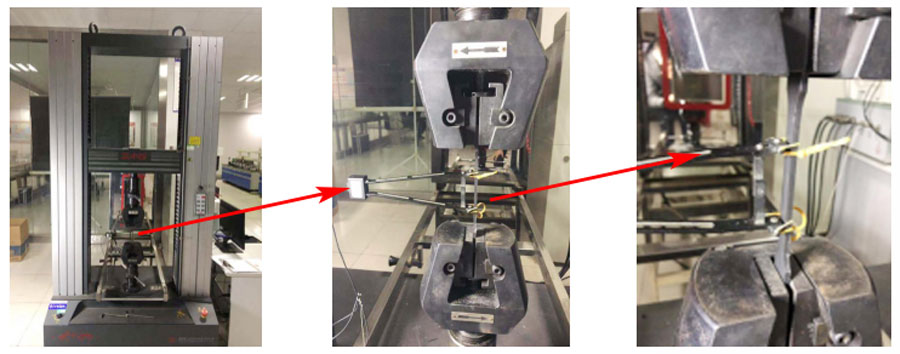

PTJ Cnc Shop Plastic Machining currently uses a resistive extensometer, model Y50 / 25, with an accuracy of 0.5, of which 50 is the gauge distance and 25 is the large amount of deformation. The installation method is to use two fingers to gently pinch the two arms of the extensometer with the positioning pin inserted, so that the sample is in contact with the arm. Use the hooks of the two arms of the extensometer to fix the extensometer on the test with rubber bands. Pulling out the positioning pin changes the movement of the arm. Note that the blade line of the two arms must be centered and parallel to the axis of the sample.

Strain Gauge Method

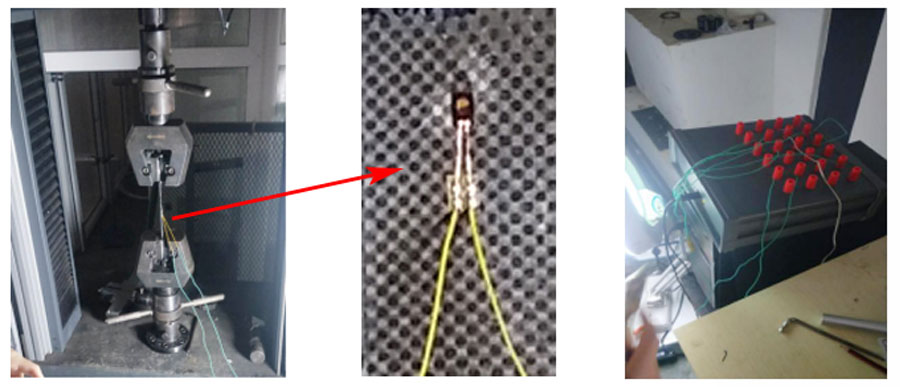

The strain gauge is a strain gauge that changes its resistance value as the deformation sticks to the surface of the sample in a prescribed direction, and the resistance value of the strain gauge changes due to the strain on the surface of the sample. Also called resistance strain gauge method. It can be divided into three categories: static strain gauge, dynamic strain gauge, static and dynamic strain gauge, wired strain gauge, foil strain gauge, and semiconductor strain gauge. In addition, the strain gauge is equipped with corresponding sensors, which can measure physical quantities such as force, mass, pressure, displacement, torque, and speed and their dynamic changes.

The calculation of the PEEK tensile elastic modulus is based on the load stress on the sample measured by the large sensor of the main beam of the testing machine, and the strain measured by the extensometer method and strain gauge method, and calculated by the modulus formula.

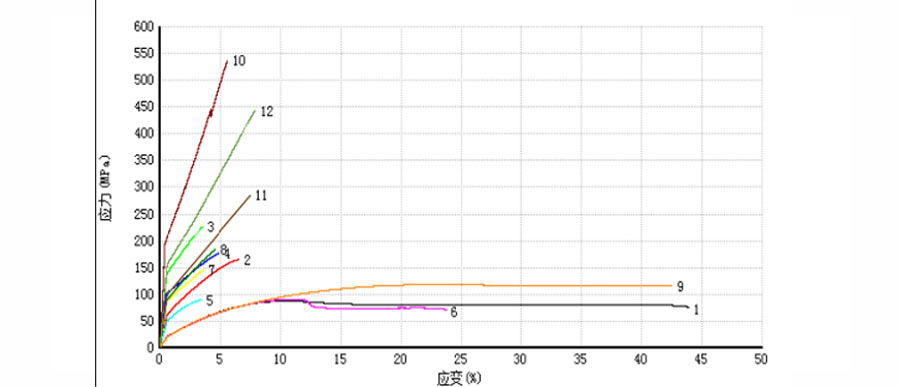

The following is the PEEK tensile stress-strain curve of the materials currently on sale at PTJ Shop. The slope of the curve is the modulus of the material, measured using a Y50 / 25 resistive extensometer.

Note: 1—PEEK5600G 2—PEEK5600GF30 3—PEEK5600CF30 4—PEEK5600LF30

5—PEEKFE20 6—30% PEI + PEEK 7—Crosslinked PPSGF40 8—Linear PSSGF40

9—YS2722 10—CF / PEEK 11—GF / PEEK 12—GF / PPS)

PTJ Shop is a full industrial chain company with both PEEK (polyetheretherketone) resin polymerization, continuous extrusion molding of profiles such as plate and rod, and the development, production and sales of finished parts. PEEK (polyether ether ketone) is widely used in aerospace, defense industry, automobile manufacturing, electronics and electrical, medical and other fields due to its excellent comprehensive properties.

PEEK5600G pure material, although the material’s tensile elastic modulus is only 4GPa, it also has much better performance than conventional materials such as PE, PVC, POM, PC, etc., and can replace these conventional plastic materials in many fields.

The tensile modulus of PEEK5600CF30 material after reinforcement modification can reach 20GPa, which can fully meet the performance requirements of products in many fields.

In the fields of aerospace, defense industry, and medical equipment, the material requires higher tensile elastic modulus. Conventional PEEK5600CF30 cannot meet the requirements. Jiangsu Junhua Special Plastic has developed continuous CF / PEEK thermoplastic composite materials The tensile elastic modulus can reach 60GPa, which can fully meet the demanding requirements of aerospace, defense industry and medical equipment.